| Item | Name | parameter | ||

| TD0308 | TD0309 | TD0608 | ||

| Dimension and machining accuracy of header pipe. | Header material | SA106-C, 12Cr1MoVG, P91, P92 (Maximum hardness at splicing weld: 350HB | CS - SA 106 Gr. B(The maximum hardness at the splice weld is 350HB) | |

| Outer diameter range of header | φ60-φ350mm | φ100-φ600mm | ||

| Header length range | 3-8.5m | 3-7.5m | ||

| Header thickness range | 3-10mm | 15-50mm | ||

| Drilling diameter (one time forming) | φ10-φ64mm | ≤φ50mm | ||

| Processing diameter of nesting (one time forming) | φ65-φ150mm | |||

| Straight section l of outermost hole edge to end | ≥100mm | |||

| CNC dividing head | Quantity | 2 | 1 | |

| Slewing speed | 0-4r/min(CNC) | |||

| Vertical stroke | ±100mm | ±150mm | ||

| Horizontal stroke | 500mm | |||

| Vertical feed rate mode | Inching | |||

| Horizontal feed speed mode | Inching | |||

| Drilling head and its vertical ram | Drilling spindle taper hole | BT50 | ||

| Spindle RPM | 30~3000 r/min(Stepless adjustable) | |||

| Z-stroke of drilling head | About 400mm | About 500mm | ||

| Drilling head stroke in Y direction | About 400mm | |||

| Maximum moving speed of drilling head in Z direction | 5000mm/min | |||

| Maximum moving speed of drilling head in Y direction | 8000mm/min | |||

| Driving mode | Servo motor + ball screw | |||

| Gantry | Gantry drive mode | Servo motor + rack and pinion | ||

| Maximum stroke of x-axis | 9m | |||

| Maximum moving speed of x-axis | 8000mm/min | 10000mm/min | ||

| other | Number of CNC systems | 1set | ||

| Number of NC axes | 4 | |||

| Testing organization | 1 set | |||

| Auxiliary pressing device | 1 set | |||

| Supporting device | 1 set | |||

| NO. | Name | Brand | Country |

| 1 | CNC system | Siemens 828D | Germany |

| 2 | Feed servo motor | Siemens | Germany |

| 3 | Linear guide rail | HIWIN/PMI | Taiwan, China |

| 4 | X-axis precision reducer | ATLANTA | Germany |

| 5 | X-axis rack and pinion pair | ATLANTA | Germany |

| 6 | Precision spindle | Kenturn/Spintech | Taiwan, China |

| 7 | Spindle motor | SFC | China |

| 8 | Hydraulic valve | ATOS | Italy |

| 9 | Oil pump | Justmark | Taiwan, China |

| 10 | Drag chain | CPS | Korea |

| 11 | Automatic lubrication system | HERG | Japan |

| 12 | Button, indicator light and other main electrical components | Schneider | France |

| 13 | Ball screw | I+F/NEFF | Germany |

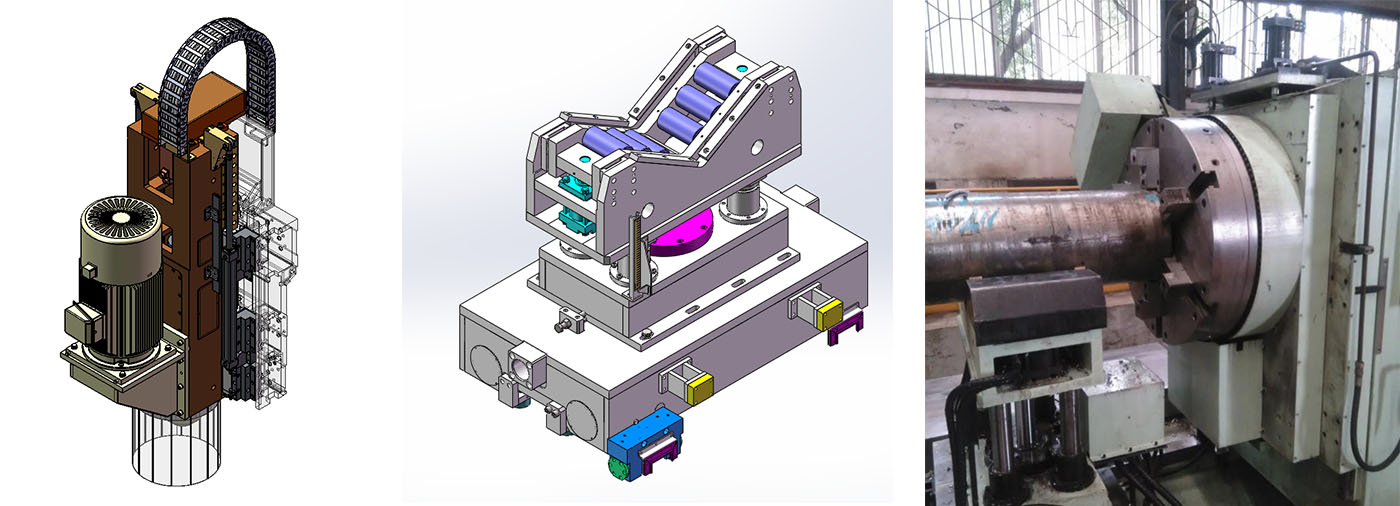

b. CNC dividing head The CNC dividing head is installed at one end of the base of the machine tool, which can move forward and backward to facilitate the loading and unloading of the header. The indexing head is equipped with a customize hydraulic chuck, which adopts a precision slewing bearing with high transmission accuracy and large torque

b. CNC dividing head The CNC dividing head is installed at one end of the base of the machine tool, which can move forward and backward to facilitate the loading and unloading of the header. The indexing head is equipped with a customize hydraulic chuck, which adopts a precision slewing bearing with high transmission accuracy and large torque c. Chip removal and cooling The gutter under the base is equipped with a flat chain chip conveyor, which can be automatically discharged into the debris carrier at the end. Cooling pump is provided in the coolant tank of chip conveyor, which can be used for external cooling of tool to ensure drilling performance and service life of drill bit. The coolant can be recycled.

c. Chip removal and cooling The gutter under the base is equipped with a flat chain chip conveyor, which can be automatically discharged into the debris carrier at the end. Cooling pump is provided in the coolant tank of chip conveyor, which can be used for external cooling of tool to ensure drilling performance and service life of drill bit. The coolant can be recycled. d. Lubrication system The machine tool adopts the combination of automatic lubrication system and manual lubrication to lubricate all parts of the machine too., which avoids the tedious manual operation and improves the service life of each part.

d. Lubrication system The machine tool adopts the combination of automatic lubrication system and manual lubrication to lubricate all parts of the machine too., which avoids the tedious manual operation and improves the service life of each part. e. Electric control system The CNC system adopts Siemens SINUMERIK 828d CNC system. SINUMERIK 828d is a panel based CNC system. The system integrates CNC, PLC, operation interface and measurement control loop.

e. Electric control system The CNC system adopts Siemens SINUMERIK 828d CNC system. SINUMERIK 828d is a panel based CNC system. The system integrates CNC, PLC, operation interface and measurement control loop.