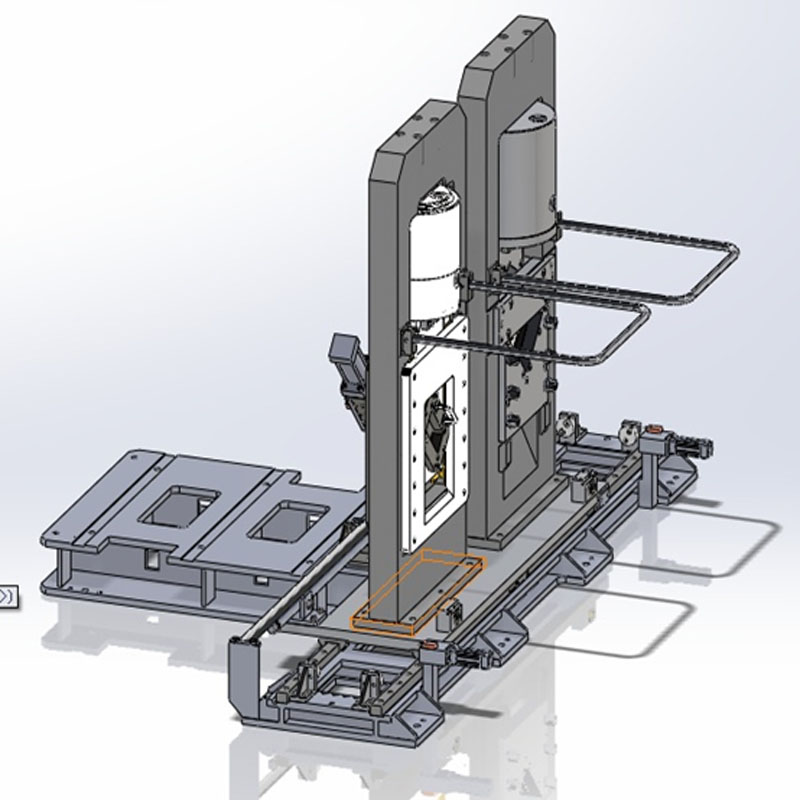

| Working material range | 80x43x5~140x60x8mm(U Channel) |

| 40x3-80x8mm(Flat bar) | |

| Material type | Q235 |

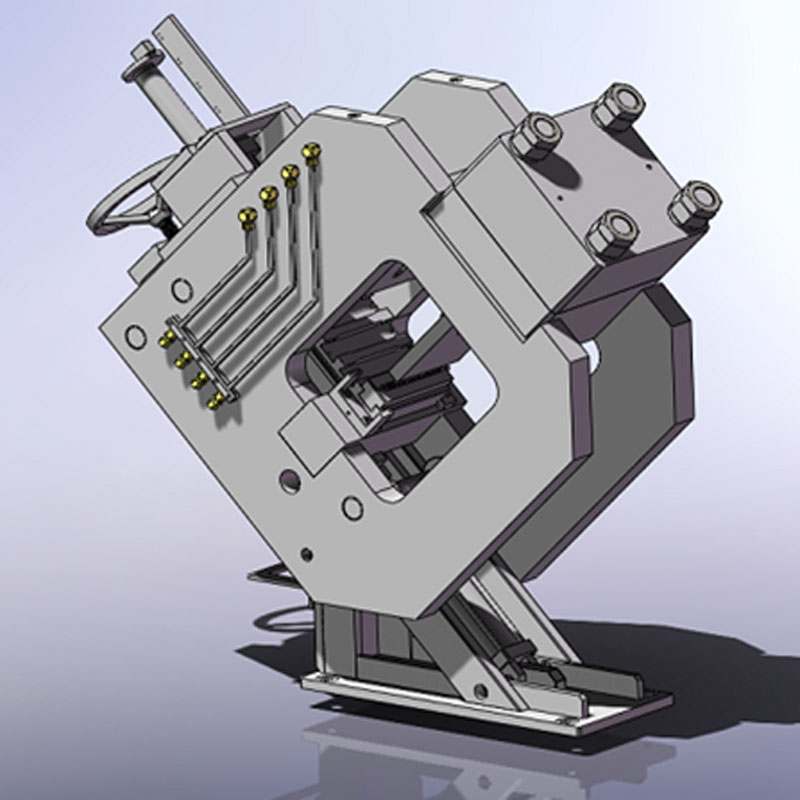

| Punching nominal force | 950KN |

| Maximum punching diameter | φ26mm(Round hole) |

| φ22x60mm(Oval hole) | |

| Number of punching positions | 3 |

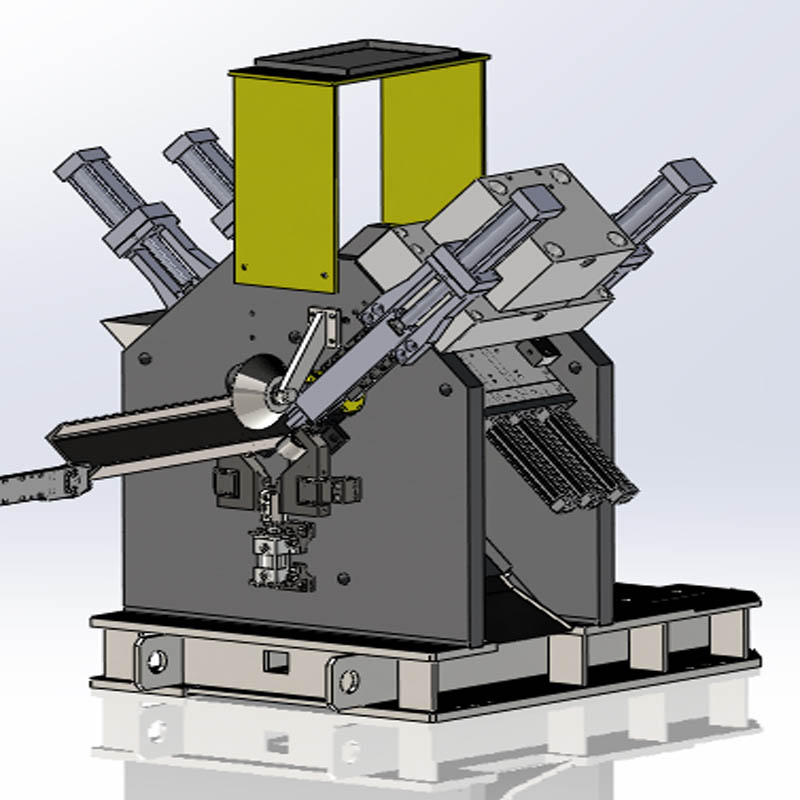

| Marking nominal force | 630 KN |

| Number of marking groups | 4 |

| Number of marking per group | 10 |

| Character size | 14x10x19mm |

| Nominal shear force | 750KN(strip steel) |

| 1000KN(Channel -steel) | |

| Cut off mode | Single blade shearing |

| Maximum raw material length | 9m |

| Maximum finished material length | 3m |

| Machining accuracy | Meet the requirements of GB / T 2694-2010 |

| Cooling mode | water cooling |

| Total power of equipment | 33KW |

| Machine dimensions | 27x9x2.2m |

| Net weight | About 14tons |

| NO | Name | Brand | Country |

| 1 | AC servo motor | Delta/Schneider | Taiwan, China / France |

| 2 | PLC | Yokogawa/ Schneider | Japan / France |

| 3 | Input module | Yokogawa/ Schneider | Japan / France |

| 4 | output module | Yokogawa/ Schneider | Japan / France |

| 5 | Positioning module | Yokogawa/ Schneider | Japan / France |

| 6 | Contactor | Siemens | Germany |

| 7 | Motor switch | Siemens | Germany |

| 8 | Supporting chain | Kabel | Germany |

| 9 | Electromagnetic unloading valve | ATOS | Italy |

| 10 | Relief valve | ATOS | Italy |

| 11 | Electro hydraulic directional valve | JUSTMARK | Taiwan, China |

| 12 | Drag Plate | AirTAC | Taiwan, China |

| 13 | Air valve | AirTAC | Taiwan, China |

| 14 | Cylinder | SMC | Japan |

| 15 | Duplex | SMC | Japan |

2. The material is clamped by pneumatic clamp and moves quickly for positioning. The material is driven by servo motor and driven by gear rack, with high positioning accuracy. 3. The cross transverse conveyor is composed of four chains with shifting blocks and frame body, and the chain is driven by motor through reducer. 4. The output conveyor is composed of conveyor and cylinder. After the finished material comes out of the main machine part, it is rotated and sent out of the production line.

2. The material is clamped by pneumatic clamp and moves quickly for positioning. The material is driven by servo motor and driven by gear rack, with high positioning accuracy. 3. The cross transverse conveyor is composed of four chains with shifting blocks and frame body, and the chain is driven by motor through reducer. 4. The output conveyor is composed of conveyor and cylinder. After the finished material comes out of the main machine part, it is rotated and sent out of the production line. 5. The machine has three CNC axes: the movement and positioning of the feeding trolley and the up & down movement and positioning of the punching tools. 6. The computer programming is easy, and can display the material graphics and the coordinate size of the hole position, which is convenient for inspection. The upper computer management is adopted, which greatly facilitates the storage and call of the program; Graphic display; Fault diagnosis and remote communication. 7. Cooling mode of hydraulic power pack: water cooling or air cooling (optional).

5. The machine has three CNC axes: the movement and positioning of the feeding trolley and the up & down movement and positioning of the punching tools. 6. The computer programming is easy, and can display the material graphics and the coordinate size of the hole position, which is convenient for inspection. The upper computer management is adopted, which greatly facilitates the storage and call of the program; Graphic display; Fault diagnosis and remote communication. 7. Cooling mode of hydraulic power pack: water cooling or air cooling (optional).