| NO | Item | Parameter | |||

| PM20A | PM25B | PM30B | |||

| 1 | Maximum material size | Processing dimension | Φ800~Φ2000mm | φ1000~φ2500mm | φ1300~φ3000mm |

| Maximum material thickness | 300 mm | ||||

| 2 | Rotary table (C-axis) static pressure | Diameter of rotary table | 2000mm | Ф2500 mm | Ф3000 mm |

| T-slot width | 36 mm | ||||

| Load-bearing | 3T/m | 30T | 40T | ||

| Set minimum indexing unit | 0.001° | ||||

| C-axis rotation speed | 0-1r/min | ||||

| C-axis positioning accuracy | 8"(Special customization) | ||||

| C-axis repeat positioning accuracy | 4"(Special customization) | ||||

| Weight | 17Tons | 17Tons | 19 Tons | ||

| 3 | Headstock | Maximum borehole diameter | Φ96mm | Φ60 mm(Carbide drill) | Φ70 mm(Carbide drill) |

| Maximum tapping diameter | M30 | M45 | M56 | ||

| Maximum speed of spindle | 3000r/min | 2000r/min | |||

| Spindle taper | BT50 | ||||

| Spindle motor power | 45KW | 30/41kW | 30/45kW | ||

| Maximum torque of spindle ≤ 250r / min | 1140/1560Nm | ||||

| Variable box | 1:1.2/1:4.8 | ||||

| Distance between spindle end face and rotary table | 400-900mm | 400-1050mm | |||

| Distance from spindle axis to rotary table center | 500-1700mm | 650-1850mm | |||

| 4 | Hydraulic system | Hydraulic pump pressure / flow | 6.5Mpa/25L/min | ||

| Motor power of hydraulic pump | 3KW | ||||

| 5 | Electrical system | Numerical control system | Siemens 828D | ||

| Number of CNC axes | 3+1 | 3+1 | 3+1 | ||

| Total power of motor | about 75kW | about 50kW | about 70kW | ||

| 6 | Machine dimensions(L*W*H) | About5.8*4.2*5m | about 6.3*4.7*5m | ||

| 7 | Main machine weight | ≥17Tons | Machine: 20T Hydrostatic turret:17T | Machine: 20T Hydrostatic turret:19T | |

8. The CNC system of this machine adopts Spanish FAGOR8055, with electronic hand wheel, powerful function and simple operation. It is equipped with upper computer and RS232 interface, and has the functions of processing preview and review. The operation interface has the functions of man-machine dialogue, error compensation and automatic alarm.

8. The CNC system of this machine adopts Spanish FAGOR8055, with electronic hand wheel, powerful function and simple operation. It is equipped with upper computer and RS232 interface, and has the functions of processing preview and review. The operation interface has the functions of man-machine dialogue, error compensation and automatic alarm. | NO | Name | Brand | Country |

| 1 | Roller linear guide | HIWIN | Taiwan, China |

| 2 | Ball screw | NEFF/IF | Germany |

| 3 | Ф 2500 rotary table (static pressure) | JIER Tool Machine Group | China |

| 4 | Numerical control system | Siemens 828D | Germany |

| 5 | Feed servo motor and driver | Siemens | Germany |

| 6 | Main motor | Siemens | Germany |

| 7 | Grating ruler | FAGOR | Spain |

| 8 | Spindle | Kenturn | Taiwan, China |

| 9 | Hydraulic valve | ATOS | Italy |

| 10 | Oil pump | Justmark | Taiwan, China |

| 11 | Automatic lubrication system | BIJUR | USA |

| 12 | Cooling pump | Fengchao Pumps | China |

| 13 | Button, indicator light and other main electrical components | Schneider | France |

| 14 | Transmission case | GTP | Taiwan, China |

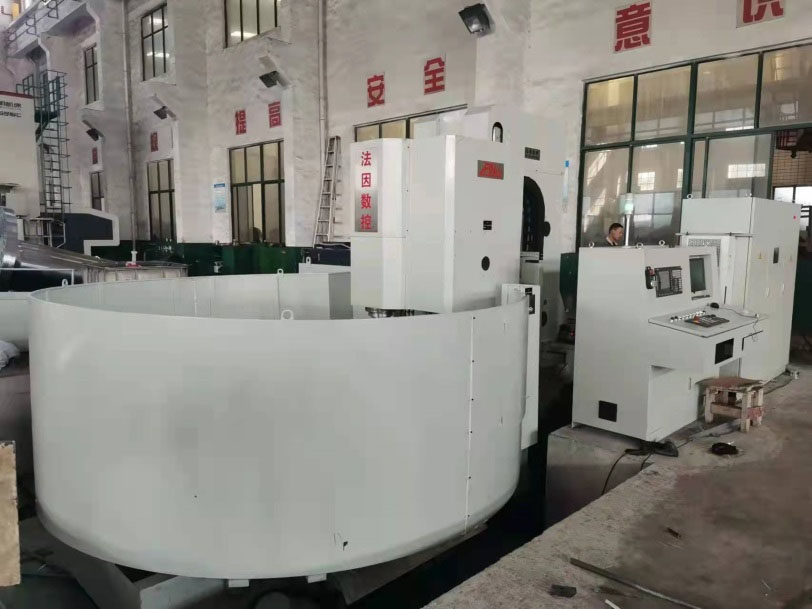

1. The machine is mainly composed of bed and longitudinal slide, gantry and transverse slide, automatic clamping chuck, vertical ram drilling head, hydraulic system, cooling system, electrical system, automatic lubrication and other parts.

1. The machine is mainly composed of bed and longitudinal slide, gantry and transverse slide, automatic clamping chuck, vertical ram drilling head, hydraulic system, cooling system, electrical system, automatic lubrication and other parts.  4. Taiwan precision spindle (internal cooling) is adopted for the drilling spindle of this machine. The spindle taper hole BT50 has butterfly spring automatic broach mechanism. 5. The automatic clamping chuck is used to clamp the annular material automatically, and the clamping force is easy to adjust. The chuck is separated from the bed to realize fast automatic clamping and reliable operation. 6. The X-axis guide rails on both sides of the machine are installed with stainless steel protective cover, and the Y-axis guide rails are installed with flexible protective cover at both ends, with soft limit function. 7. The machine is equipped with flat chain chip conveyor, chip receiving box is flip type, and cooling system with paper filter, and the coolant is recycled.

4. Taiwan precision spindle (internal cooling) is adopted for the drilling spindle of this machine. The spindle taper hole BT50 has butterfly spring automatic broach mechanism. 5. The automatic clamping chuck is used to clamp the annular material automatically, and the clamping force is easy to adjust. The chuck is separated from the bed to realize fast automatic clamping and reliable operation. 6. The X-axis guide rails on both sides of the machine are installed with stainless steel protective cover, and the Y-axis guide rails are installed with flexible protective cover at both ends, with soft limit function. 7. The machine is equipped with flat chain chip conveyor, chip receiving box is flip type, and cooling system with paper filter, and the coolant is recycled.