| NO | Item | Parameter | ||||||

| BHD500A-3 | BHD700-3 | BHD1005A-3 | BHD1206A-3 | BHD1207A-3 | ||||

| 1 | H-beam | Web height | 100-500mm | 150~700mm | 150-1000mm | 150~1250mm | 150~1250mm | |

| 2 | Flange width | 75~400mm | 75~400mm | 75-500mm | 75~600mm | 75~700mm | ||

| 3 | U-shaped | Web height | 100-500mm | 150-700mm | 150~1250mm | 150~1250mm | ||

| 4 | Flange width | 75~200mm | 75~200mm | 75~300mm | 75~350mm | |||

| 5 | Beam length | 1500 ~12000mm | 1500 ~12000mm | 1500 ~15000mm | ||||

| 6 | Maximum thickness of beam | 20mm | 80mm | 60mm | 75mm | 80mm | ||

| 7 | Drilling spindle | Quantity | 3 | 3 | 3 | 3 | 3 | |

| 8 | Maximum drilling hole diameter | Carbide:φ 30mm High speed steel:φ 35mm Left and right units: φ 30mm | Carbide:ф 30mm High speed steel:ф 40mm | Carbide: ∅ 30mm High speed steel: ∅ 40mm | Carbide: ∅30mm High-speed steel: ∅40mm | Left,Right:∅40mm Upl:¢50mm | ||

| 9 | Spindle taper hole | BT40 | BT40 | BT40 | BT40 | |||

| 10 | Spindle motor power | Left,Right: 7.5KWUp: 11KW | 3×11KW | 3×11KW | 3*11KW | Left,Right: 15KWUp: 18.5KW | ||

| 11 | Tool magazine | Quantity | 3 | 3 | 3 | 3 | 3 | |

| 12 | Number of tool positions | 3×4 | 3×4 | 3×4 | 3×4 | 3×4 | ||

| 13 | CNC axis | Quantity | 7 | 7+3 | 7 | 6 | 7 | |

| 14 | Servo motor power of fixed side, moving side and middle side feed spindle | 3×2kW | 3×3.5kW | 3×2KW | 3×2kW | 3×2kW | ||

| 15 | Fixed side, moving side, middle side, moving side positioning axis servo motor power | 3×1.5kW | 3×1.5kW | 3×1.5KW | 3×1.5kW | 3×1.5kW | ||

| 16 | Up and down movement distance of fixed side and mobile side | 20-380mm | 30~370mm | |||||

| 17 | Left and right horizontal distance of middle side | 30-470mm | 40~760 mm | 40~760 mm | ||||

| 18 | Width detection stroke | 400mm | 650mm | 900mm | 1100mm | 1100mm | ||

| 19 | Web detection stroke | 190mm | 290mm | 290mm | 290mm | 340mm | ||

| 20 | Feeding trolley | Power of servo motor of feeding trolley | 5kW | 5kW | 5kW | 5kW | 5kW | |

| 21 | Maximum feeding weight | 2.5Tons | 10 Tons | 8Tons | 10 Tons | 10 Tons | ||

| 22 | Up and down (vertical) stroke of clamping arm | 520mm | ||||||

| 23 | Cooling mode | Internal cooling + external cooling | Internal cooling + external cooling | Internal cooling + external cooling | Internal cooling + external cooling | Internal cooling + external cooling | ||

| 24 | Electrical system control | PLC | PLC | PLC | PLC | PLC | ||

| 25 | Overall dimension of main machine (L x W x H) | About 5.6×1.6×3.3m | About 6.0×1.6×3.4 m | |||||

| 26 | Main machine weight | About 7500kg | About 7000Kg | About 8000kg | ||||

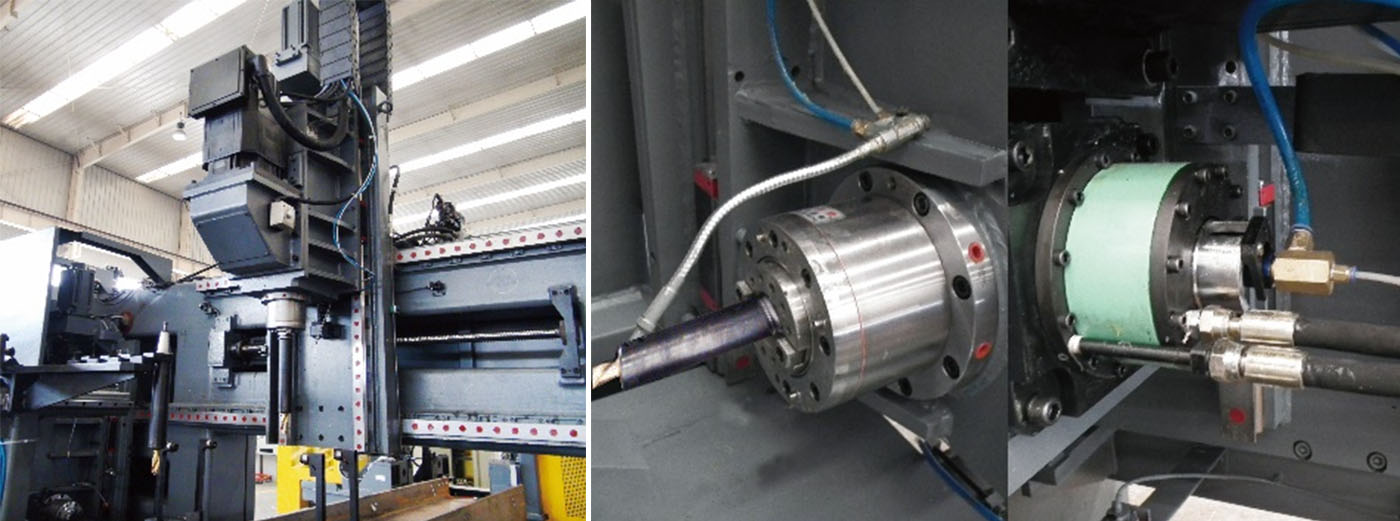

3. There are three spindle boxes, which are respectively installed on three CNC sliding tables for horizontal and vertical drilling. Each spindle box can be drilled separately or at the same time. 4. The spindle adopts precision spindle with high rotation precision and good rigidity. Machine with BT40 taper hole, it is convenient for tool changing, and can be used to clamp twist drill and carbide drill.

3. There are three spindle boxes, which are respectively installed on three CNC sliding tables for horizontal and vertical drilling. Each spindle box can be drilled separately or at the same time. 4. The spindle adopts precision spindle with high rotation precision and good rigidity. Machine with BT40 taper hole, it is convenient for tool changing, and can be used to clamp twist drill and carbide drill. 5. The beam is fixed by hydraulic clamping. There are five hydraulic cylinders for horizontal clamping and vertical clamping respectively. The horizontal clamping is composed of fixed side reference and moving side clamping. 6. In order to meet the processing of multiple hole diameters, the machine is equipped with three in-line tool magazine, each unit is equipped with a tool magazine, and each tool magazine is equipped with four tool positions.

5. The beam is fixed by hydraulic clamping. There are five hydraulic cylinders for horizontal clamping and vertical clamping respectively. The horizontal clamping is composed of fixed side reference and moving side clamping. 6. In order to meet the processing of multiple hole diameters, the machine is equipped with three in-line tool magazine, each unit is equipped with a tool magazine, and each tool magazine is equipped with four tool positions.| No. | Name | Brand | Country |

| 1 | Spindle | Keturn | Taiwan, China |

| 2 | Linear rolling guide pair | HIWIN/CSK | Taiwan, China |

| 3 | Hydraulic pump | JUSTMARK | Taiwan, China |

| 4 | Electromagnetic hydraulic valve | ATOS/YUKEN | Italy / Japan |

| 5 | servo motor | Siemens / MITSUBISHI | Germany / Japan |

| 6 | Servo driver | Siemens / MITSUBISHI | Germany / Japan |

| 7 | Programmable controller | Siemens / MITSUBISHI | Germany / Japan |

| 8 | Computer | Lenovo | China |

| 9 | PLC | Siemens / Mitsubishi | Germany / Japan |

Note: The above is our standard supplier. It's subject to be replaced by same quality components of other brand if the above supplier can't supply the components in case of any special matter.

7. The machine is equipped with beam width detection and web height detection device, which can effectively compensate the deformation of the beam and ensure the machining accuracy; The two kinds of detection devices adopt the wire encoder, which is convenient to install and reliable to work. 8. The machine adopts the trolley feeding, and the CNC clamp feeding mechanism is composed of servo motor, gear, rack, detection encoder, etc. 9. Each spindle box equipped with its own external cooling nozzle and internal cooling joint, which can be selected according to the needs of drilling. Internal cooling and external cooling can be used separately or at the same time.

7. The machine is equipped with beam width detection and web height detection device, which can effectively compensate the deformation of the beam and ensure the machining accuracy; The two kinds of detection devices adopt the wire encoder, which is convenient to install and reliable to work. 8. The machine adopts the trolley feeding, and the CNC clamp feeding mechanism is composed of servo motor, gear, rack, detection encoder, etc. 9. Each spindle box equipped with its own external cooling nozzle and internal cooling joint, which can be selected according to the needs of drilling. Internal cooling and external cooling can be used separately or at the same time.